Nexus Project Experiments Continue to Advance Agricultural Innovations

1. Biochar Preparation: Wet Biochar Crushing

Biochar particle size has a great impact on its physical properties such as total porosity and BET surface area, which enhance water-holding capacity and growth of soil microbial community. Therefore, among the post-processing treatments of biochar, crushing/grinding is a key factor in improving the properties of biochar. Many low-tech pyrolysis methods are accompanied by a water quenching process to terminate combustion and cool down. Because the biochar produced in this way is wet, crushing it with a widely used hammer mill causes clogging. As a cost-effective solution, we built a wet biochar crusher using a sink disposal for a total cost of approximately $300. This method effectively crushes biochar without clogging. We are also working on another wet biochar crusher using a sewage pump, which is expected to be quicker and more robust than the disposal while requiring less water to operate. Each method produces noticeably different average particle sizes. We will compare particle size distributions from different methods of wet biochar crushing, so this information will be useful in developing methods of processing biochar to address specific soil issues (soil degradation, soil compaction, etc.).

|  |

| Figure 1.1 Hammer mill (left) | Figure 1.2 Sink disposal crusher (right |

2. Biochar Kiln Loaner Program

Biochar kilns are generally the most expensive equipment required to make biochar at a farm scale. We built a series of 5 “flame-cap” kilns (USDA Oregon Kiln design) and initiated a kiln loaner program to equip farmers with the means to produce their own biochar safely and effectively. These kilns are simple and easy to use, but are capable of transforming large volumes of wood waste into biochar. These kilns have a volume of approximately 35ft3 (260 gallons) and can produce about 13ft3 (100 gallon) of biochar per batch. The entire process takes between 3-4 hours. The kilns have been loaned and used by local farms and community members. We are collecting data from users on volumes of biochar produced, farm demographics, kiln performance and feedback: how farmers are using biochar and effects they are seeing.

|

| Figure 2. Community biochar making (Boone, NC) |

3. Biochar Soil Amendment

3.1. Rapid Restoration of Degraded Soil with Biochar

A long-term experiment to study the effects of using biochar along with other regenerative practices to restore degraded soil was initiated in the fall of 2022. The raised bed at the Nexus was split to four plots: two plots were treated with biochar charged in Home Biogas® effluent while the other two plots were only treated with Home Biogas® effluent. A winter rye cover crop was grown during the winter of 2022/2023 and cut in the spring. The yield of each plot was returned as a green mulch to its respective plot. Currently, eggplant is growing in the four plots. When it is harvested, yields will be compared and another cover crop will be sown for the winter. This experiment will showcase how, over time, biochar affects the health of soil. It will also help identify means of maximizing biochar’s potential in soil restoration.

|

| Figure 3. Eggplants and winter rye cuts |

3.2. Biochar Field Trial with Hybrid Poplar at Patterson School (Caldwell County, NC)

We established hybrid poplar (Populus trichocarpa x Populus deltoids) trial plot last year at Patterson School, Lenoir, NC. We planted 24 poplar stakes in March with 12 control soil and 12 treated soil. The treated soil contained 10% volume of Home Biogas® effluent charged softwood pine biochar (2 gallons of charged biochar per tree). All poplar stacks are well established and growing. We will regularly track tree growth and analyze soil samples to determine the long-term effects of biochar-treated soil in the field.

|  |

| Figure 4.1 Hybrid poplar planting in March (left) | Figure 4.2 Well-established poplars in July (right) |

4. Efficient design of Aerated Static Pile (ASP) for cold weather

Composting in the High Country can be slow and challenging during cold-weather months. Aerated Static Pile (ASP) composting can provide better results in this area as it uses closed containers to prevent excess moisture loss and allow for greater heat retention. The ASP design study conducted at Nexus proved that an insulated, forced-air (FA) ASP system maintained higher overall O2 concentration and more uniform temperature distribution.

Compared to the non-insulated, no-FA system, it reduced labor for turning the materials by up to 75% while generating high-quality compost: the materials decomposed and homogenized faster, and reached target temperatures for pathogen destruction and weed seed sterilization more efficiently.

Further study will continue in an effort to make the system more energy efficient by controlling the forced-aeration using a O2 sensor instead of a timer. The O2 sensor will supply air to the system when microbial activity demands it, helping to reduce moisture loss through over-aeration and save on energy. Sensors to monitor temperatures in different spots of the compost pile and O2 concentration have been installed and ready to collect data.

|

| Figure 5. ASP bins for cold weather design study (from left: insulation + FA, no insulation + FA, no insulation + no FA) |

|

| Figure 6. Sensors to monitor temperature and to regulate forced-aeration for ASP |

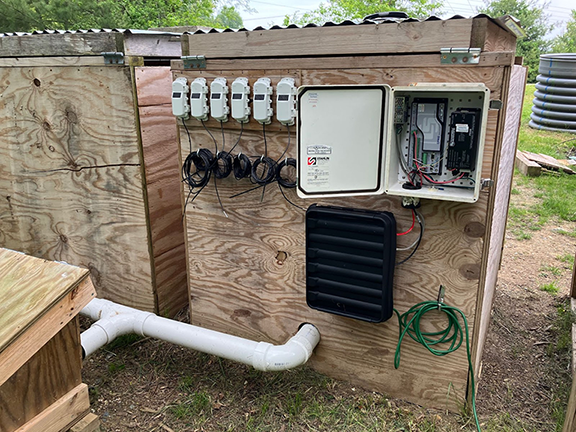

5. On-demand water heater at Springhouse farm

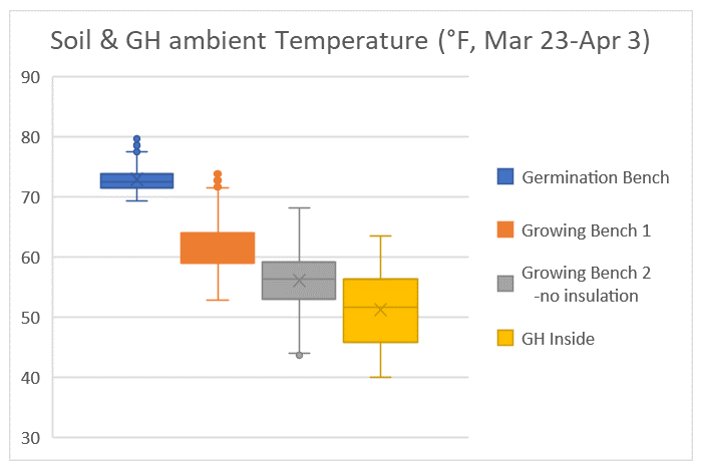

The on-demand water heater, installed in the Springhouse Farm greenhouse last fall, began operation on March 23 after undergoing test run for parameter setting in early March. The new water heater worked reliably, maintaining appropriate soil temperatures on both the germination bench and the growing benches (with/without insulation).

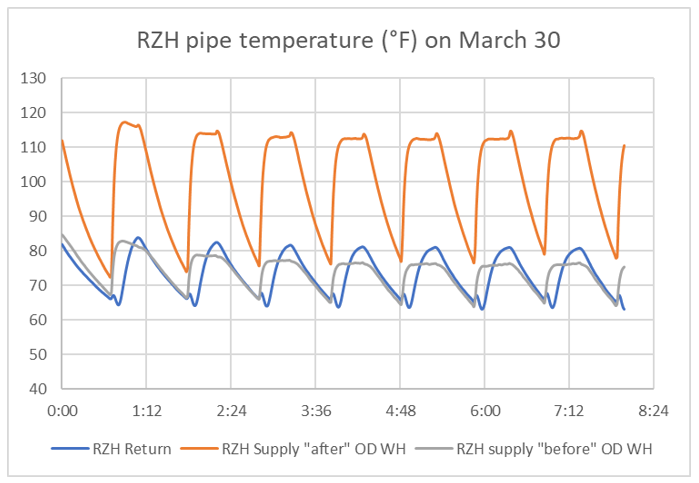

The on-demand water heater instantly raised the fluid temperature below 80°F to over 110°F, and after supplying heat energy to five benches, including the germination bench, the fluid temperature dropped to around 80°F.

Starting next year, we plan to operate the on-demand water heater throughout the cold season and begin collecting data to compare it to the previous data with the 40 gal-storage tank water heater.

|

| Figure 7. RZH pipe temperature (supply and return) |

|

| Figure 8. RZH soil temperatures vs ambient temperature |

6. Direct solar PV water heating and dynamic lighting system study for growing season extension

RIEEE’s 2024 Concert program has awarded a grant to the Nexus project. We proposed to evaluate the two sustainable technologies--a direct solar PV water heating and a supplemental light with dynamic light control (DLC)--in the Nexus greenhouse and investigate the viability to improve agricultural productivity in our region.

The price of PV modules has fallen significantly over the past decade, opening up new options for solar water heaters. By connecting the direct current (DC) output of a PV array to the DC heating element in an electric water heater, the system offers several advantages over solar thermal systems, including lower upfront cost, longer life, system simplicity, no freezing concerns, and lower maintenance. We will investigate the performance of a direct solar PV water heating system with an optimal maximum power point tracker (MPPT) using the existing PV array (eight 195 watts PV modules) next to the Nexus greenhouse.

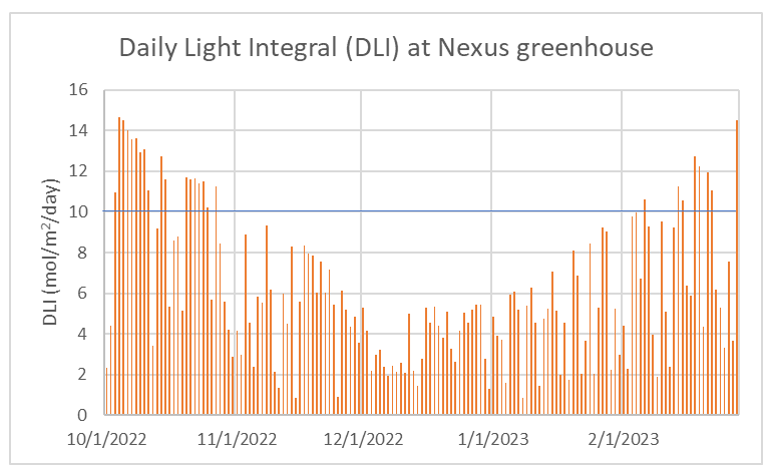

We initiated research on supplemental lighting for growing season extension in 2021. Unlike the time-controlled supplemental lighting needed for indoor farming, supplemental lighting for greenhouse production can be more efficient by using a PAR sensor to measure daily light integral (DLI) to provide the necessary amount of light for crops.

|

| Figure 9. DLI of Nexus greenhouse from Oct.2022 through Feb.2023 |

DLI of above 10 mol/m2/day is considered good for plants. Figure 9 depicts DLIs of the inside Nexus greenhouse during October 2022 through February 2023, showing lack of good light from November through February. Supplemental light adds energy consumption to greenhouse production, so several studies have been conducted to figure out an efficient way of controlling lighting systems. We will continue research on supplemental lighting in the Nexus greenhouse and conduct a study comparing power consumption and lettuce biomass under DLC and on/off switch control systems with different photosynthetic photon flux densities (PPFD) and light hours as variables (combinations resulting in a DLI of 12 mol/m2/day).