The Nexus research team is collaborating with two cooperating farms in Watauga County to pilot greenhouse heating systems that will extend the growing season by using biomass energy produced on-farm. With funding from the NC Department of Agriculture’s Bioenergy Research Initiative, the team started to build two pilot systems on local farms: Springhouse Farm in Vilas and Against the Grain Farm in Zionville. Both are small farms that intensively manage less than 20 acres and rely on considerable amounts of human labor for management and harvest. Like many small farms, both farms are poised to benefit from innovative practices and technologies that contribute to their economic and environmental sustainability. Developing affordable and sustainable season extension systems is a primary goal of the Nexus team’s research.

Following several site visits to assess farm resources, including available biomass for energy generation, the team developed a preliminary system design and greenhouse heat flow model. Cooperating farmers also visited the Nexus site located near the Watauga County Landfill to learn about, evaluate and provide feedback on the system components demonstrated there. While construction of pilot sites at Against the Grain and Springhouse begins, the team continues to refine the design with a focus on affordability and ease of operation and maintenance to ensure successful technology transfer to additional local farms in the future.

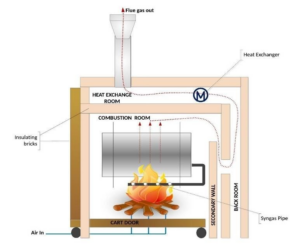

Fig 1. Rendering showing the proposed design of the biomass heating system, and the actual work in progress

Recent efforts focus on improving one component of the system: the biochar kiln. This work is supported by a student-led P3 (People, Planet, Prosperity) grant from the Environmental Protection Agency. The team is working to improve kiln door design and the efficiency of the heat exchange process and to address challenges loading and unloading feedstock. The new kiln design incorporates a rolling cart attached to the door that also serves as the floor and fourth wall of the kiln. In addition, changes to the heat exchange design were made to capture waste heat during burns and store it in a thermal battery. The updated design includes space for heat exchange and storage at the back of the firebox which is lined with hard firebrick to provide thermal mass for heat storage. Flue gas from the firebox will travel through a firebrick-lined path to exit the kiln, adding additional thermal mass to absorb heat and reduce the temperature of exhaust gasses. These improvements are expected to increase overall system efficiency.

These design changes are informed by the team’s invaluable collaboration with Springhouse and Against the Grain farms. Their contribution is key in developing innovative and affordable greenhouse heating systems that are appropriate for the scale and scope of farm operations typically found in Appalachia.