The Nexus team continues its work designing and evaluating technological solutions to extend the growing season for small-scale farmers in Southern Appalachia. The team will soon complete the second year of an on-farm pilot of two systems, one at Springhouse Farm and one at Against the Grain (ATG) Farm in the High Country area. This year’s work contributes additional evidence that effectively designed root zone heating systems can reduce fossil fuel consumption for greenhouse heating while maintaining productive growing conditions. Springhouse Farm used 30% less propane in 2019, even though heating degree days were only 100 less than the previous year. Additionally, the team reports exciting preliminary evidence that biochar improves the anaerobic digestion process. Preliminary data from bench scale tests of goat dairy feedstocks indicate that the addition of biochar stabilizes the rate of gas production, reduces retention time and increases total biogas production. The team has been busy this year, and these findings keep them excited and bode well for local farmers looking to increase production sustainably. Read more technical detail below.

The second year of the pilot system operation at partner farms

We started the second year of the pilot by upgrading bench covers to retain warmth and reduce heat loss. Growing bench covers were built using 6 mil polyethylene attached with zippers, Velcro, and magnetic strips for easy opening and closing. The germination bench cover at Springhouse farm was built using 8mm polycarbonate twin-wall panels which have twice the R value of 6 mil polyethylene. This upgrade supports improved germination by maintaining a consistent soil temperature (Fig 1).

Following these improvements at Springhouse Farm, air temperatures inside the growing and germination bench covers exceeded greenhouse air temperatures by 10 °F and 20 °F, respectively. As a result, the greenhouse space heater was not needed during Springhouse’s winter season, indicating that the root zone heating system with improved covers will perform well even without space heating. When greenhouse and outside air temperatures were lowest (31°F and 15°F, respectively), the system maintained soil temperatures of ~43°F on the growing bench without bottom insulation, 52°F on the growing bench with bottom insulation, and 73 °F on the germination bench. On the same night, the water on the table without cover and root zone heating was frozen (Fig 2). When the root zone heating system at Against The Grain (ATG) Farm was running, air temperature inside the vertical rack cover exceeded greenhouse air temperature by as much as 15°F.

Fig 1. Improved bench covers

Fig 2. March freezing day

The biochar kiln at Springhouse Farm was fired on five cloudy days in the second pilot year. These conditions – five kiln firings, improved covers, and no space heating – contributed to a 30% reduction in propane usage at Springhouse Farm compared to 2018 when the space heater was on and the biochar kiln was not fired. During the first year the pilot system operated, Springhouse Farm used 42% less propane compared to the previous year without the pilot system. Regarding heating load difference, heating degree days (HDD) from February to April was 1846 in 2018 and 1740 in 2019. In fall 2018, we harvested Sorghum-sudangrass that had been planted as a cover crop at Springhouse Farm, and dried and chipped it for use as feedstock for the biochar kiln (Fig 3). We used 35lb to 40 lb of firewood and 8 to 10 lb Sorghum-sudangrass feedstock per burn and collected around total 60,000btus over five firings.

Fig 3. Drying rack built under the shed roof and harvest day

Bench-scale AD experiments

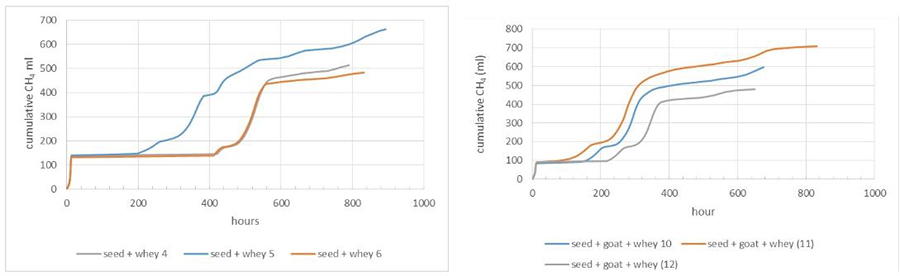

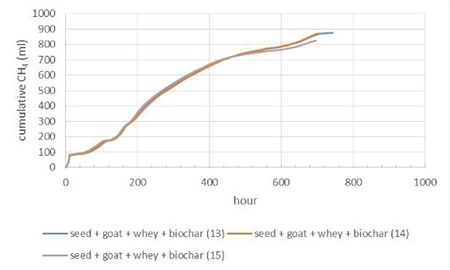

The Nexus team also performed bench scale anaerobic digestion (AD) experiments to determine the methane potential of feedstocks available to Heritage Homestead, a local goat dairy that produces cheese. Available AD feedstocks include whey and goat manure, and the team also tested the addition of biochar. We compared cumulative methane production, production rate, and retention time of four feedstock mixes to the control of seed only. Mixes tested were 1) seed with whey, 2) seed with goat manure, 3) seed with whey and manure, and 4) seed with whey, manure and biochar. The seed was taken from a Homebiogas system operating at the Nexus research facility that was fed with cow manure and treated for optimal performance.

Two whey treatments (with and without goat manure) exhibited variable gas production rates, higher retention time, and higher cumulative methane production. Treatments with goat manure were fairly balanced and quickly produced gas but exhibited low cumulative methane production. The addition of biochar appeared to stabilize the reaction, leading to more uniform performance with a very low standard deviation compared to the sample without biochar that exhibited high variability. Biochar addition also increased cumulative methane production and reduced retention time. (Fig 4)

Fig 4. Bench scale AD experiment data