Last semester, Nexus served App State and the greater community as a center for education, research, and outreach. A total of 16.5 hours of field days were conducted at Nexus, including five App State classes, one tour for App State’s Renewable Energy Initiative student group, and one biochar workshop. Research on biochar production and preparation continued, and a long-term evaluation study of biochar soil application was initiated. Cheese whey-BCAD research and greenhouse energy efficiency research in cooperation with local businesses continued in more creative ways.

1. Biochar preparation

After producing biochar, it must go through crushing and charging processes to effectively apply it to the soil. For our production demonstration, we used a hammer mill to crush biochar. The hammer mill performed well in making a very fine uniform particle size (1-2 mm) of char ready for inoculation. Our current inoculation system is small-scale: mixing Home Biogas® effluent and biochar in a 5-gallon bucket using a drill and paint mixer and letting the mixture sit for 2-4 days before applying to soil. However, the use of a hammer mill should be done with dry char to avoid clogging and the need for excessive cleaning. This dry process is especially dusty and must be performed outside with appropriate personal protective equipment.

In December 2022, we received internal funding ($1500) from REI to explore wet milling of biochar. Wet milling will allow us to crush char right after production as water is used to quench the burn. We will try to two techniques: a commercial grade food disposal, and a trash pump. If these techniques look promising, then it will be possible to combine the crushing and inoculation into one step while eliminating the time and labor-intensive drying step. This potential improvement could mean significant efficiency gains in the production of soil-ready biochar at the farm-scale.

|  |

| Figure 1.Hammer milling dry biochar at Nexus | Figure 2.Small-scale biochar inoculation withdigester effluent & char with drill mixing |

2. “Oregon Kiln”

We have built 5 biochar kilns based on the USDA’s “Oregon Kiln” Design. These stackable kilns are intended to be taken into the field, “to the biomass” to make char in-site. With a volume of more than 30ft3 these kilns have significant production capacity for on-farm use. We have demonstrated the kiln at Nexus, given one to our research partner the Patterson School for their biochar production, and offered extended loans of the kilns to our current partner farms.

|

| Figure 3. Oregon Kiln |

3. Biochar soil amendment

We initiated long-term evaluation of various biochar amended soils at Nexus and Patterson school.

We will establish a hybrid poplar (Populus trichocarpa x Populus deltoids) plot at Patterson School farm to investigate changes in soil health and the growth of hybrid poplar over time before and after application of biochar. To this end, we conducted soil sampling and plot mark-offs, and hybrid poplars will be planted with cuttings in March 2023.

At our Nexus research facility, we have set up biochar demonstration plot in a raised bed with degraded soil (subsoil). The raised bed divided into 4 partitions. Two of them were treated with inoculated biochar. Prior to application to the soil, hardwood biochar produced in an open pit were inoculated with Home Biogas® effluent for 2 days: 4 gallons of effluent added to 6.6 gallons of biochar for one partition. The other two were directly sprayed with 4 gallons of Home Biogas® effluent.

Each soil sample was tested to determine the initial soil condition, and winter rye seeds were planted uniformly in the soil.

|

| Figure 4. Adding inoculated biochar to long-term raised bed experiment at Nexus |

4. BCAD (biochar anaerobic digestion) research with Ashe County Cheese whey

Last year, we tried to determine the methane potential of cheese whey produced from a local cheese factory (Ashe County Cheese) under BCAD conditions. In the Fall 2022 semester, we intended to investigate the start-up conditions under which bacteria obtained from Nexus’ Home Biogas® adapt well to cheese whey substrates, and to obtain good acclimated inoculum for future cheese whey AD research.

Nexus’ Home Biogas® initially started with cow manure and then it was fed with food waste for about 4 years. The process of adapting inoculum cultured in a different environment to a new substrate--in this case, cheese whey--is important and critical.

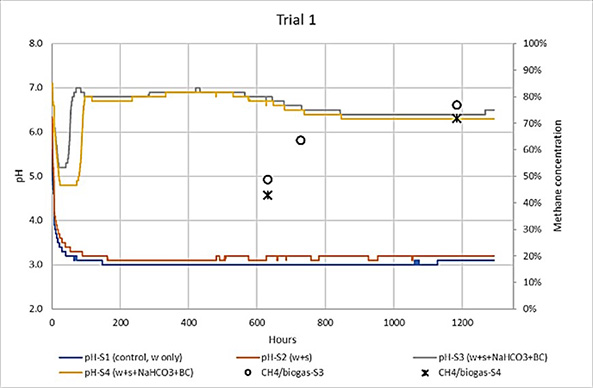

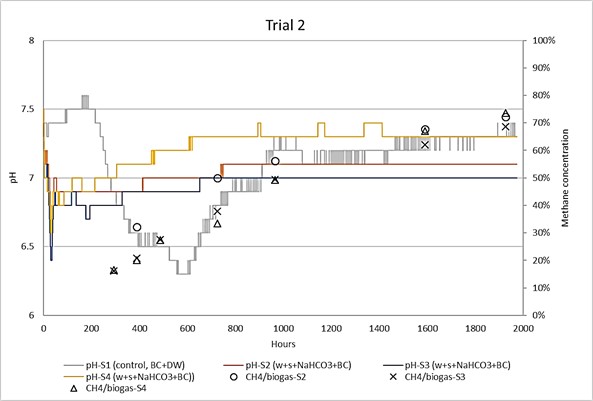

We conducted two trials. In Trial 1, the inoculum collected from Nexus’ Home Biogas® was stored at room temperature for I day, whereas in Trial 2, the inoculum collected on the same day was refrigerated at 4℃ for a month and a half until use. Since cheese whey is easily acidified, it was pretreated with baking soda. The starting pH after pretreatment was 7.1 for Trial 1 and 7.4-7.5 for Trial 2. Overall pH change was observed, and methane concentration was checked during the acclimation period.

As shown in figure 5, the pH curves of all BCAD samples in both trials showed an initial sharp drop followed by a rapid rise. After the rapid change, a stable pH plateau was formed. In Trial 1, where the starting pH was 7.1, the pH gradually decreased to 6.3 after the 23rd day, and finally all gas generation stopped. The final methane concentration measured on day 49 was above 70% for both BCAD samples. In Trial 2, there was no gradual pH decrease but it took 80 days to achieve 70% methane concentration.

|

|

| Figure 5. pH and CH4 concentration in Trial 1 & 2 |

5. On-demand water heater at Springhouse Farm

Research on increasing greenhouse energy efficiency continues. An on-demand water heater was added to the system to increase solar energy collection rates and to further increase the overall efficiency of the Nexus Pilot system. Operating the new addition from this spring's greenhouse cultivation, we will monitor greenhouse, soil and fluid temperatures, and analyze overall energy efficiency to compare it to the past data.

|

| Figure 6. On-demand water heater added to Nexus system at Springhouse farm |